5 Reasons Why 2D Drafting Still Matter

You’ve created many 2D drafting as an engineer, which continue to be crucial to the production process. You may question yourself, “Why don’t we use CAD,” given the advancements in design tool capabilities.

Computer-aided design (CAD) and computer-aided manufacturing (CAM) are fantastic tools; nevertheless, they cannot do all the tasks that can be performed by 2D drawing. Eliminating the use of 2D drafting would be a disastrous decision.

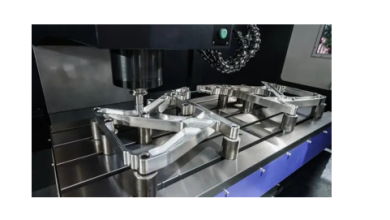

The advent of tools like Model Based Definition makes CAD seem able to do any task. You may specify tolerances and apply GD&T to your model in addition to designing and building your components in 3D. There is no need for drawing when utilising the straightforward CAM approach to generate the G-code required to execute your CNC machining programme. Is it appropriate that you may submit this straight to the manufacturer without using printed drawings?

- Not many people employ model-based definitions

Unquestionably gaining popularity is the exciting idea of model-based definition. But for this technology to work, all parties involved must accept it. The engineer developing the component and choosing the model’s tolerances represents one end in this situation. At the other end of the supply chain is the manufacturer, who builds the component after receiving the design. To use this model-based design, the manufacturer must have the correct software to access the model and its annotations. Another hurdle to overcome is referring to remarks on a 3D model rather than a 2D drafting. A computer showing the CAD must always be available, even if you have the required software. Manufacturers need technical drawings, even if you hate drawing them.

- 2D drafting are portable and simple to distribute

With the use of 2D drafting services, tolerances on crucial dimensions that must be satisfied may be easily determined. They employ printed documentation to create significant tolerances, assembly or inspection procedures, and measurement and inspection sites. These mobile sheets of paper may be posted on a wall or a notice board and annotated while the user moves.

Examining a printed drawing is often more straightforward than opening a model on a computer. You will need to measure specific dimensions on the CAD model, which is a time-consuming and temporary fix if the model-based specification has not been developed. On the production floor, there won’t always be a computer available for you to see the CAD. A 3D model with all its comments and annotations cannot currently be printed efficiently; maybe this will change in the future.

- It is simpler to annotate a 2D drafting

Consider that you are attending to a problem while observing a manufacturing line. While discussing concepts with another engineer, a surprising realisation suddenly dawns on you. Are you going to CAD your idea on a computer? Or do you want to sketch it while the concept is still fresh in your head onto an existing 2D drafting? A 2D drafting is a great technique to capture inspiration and communicate new ideas.

- The necessary data are easily represented in 2D drafting

Good drawings explain what is permitted and why it is crucial. The measurements need not be included on a drawing since they are all kept in the CAD model. You may create a comprehensive, condensed, tidy engineering drawing by including the relevant dimensions. The audience understands the significance of what you have stated and agrees that it should be considered.

Additionally, they provide essential inspection locations and clarify how assembly component assemblies are done. Your drawings serve as a critical source of information for quality assurance.

The most significant way to represent certain design aspects is still via 2D drafting. For instance, the tap size and depth must always be marked on holes that have been tapped. The completeness of the information should also be emphasised. If they are coupled to another component in an assembly, be sure to provide any crucial dimensions and tolerances.

- Words can be better than models

Mechanical engineering services use computers to view CAD models. Words become crucial when there is no other way to convey the whole tale. The dimensions, GD&T, title block, and comments on 2D drafting characterise the component or assembly. The page includes all the necessary information. Even graphic books need text because narration, labelling, and sound effects help progress the tale. You may now take a design from idea to reality with the help of 2D drafting, which have expanded to include all the data required to build a component.

Conclusion

With such compelling reasons in favour of retaining 2D engineering drawings, the use of CAD is now an essential element in the design process. The design process used to be much more manual. 2D drafting are here to stay because of how useful they are, and you don’t have to spend all day doing them since they are quick and easy to complete. The process will be simplified if you provide just the requested information, saving time for you and the manufacturer due to this change.